Making sage work for business

SICON MANUFACTURING

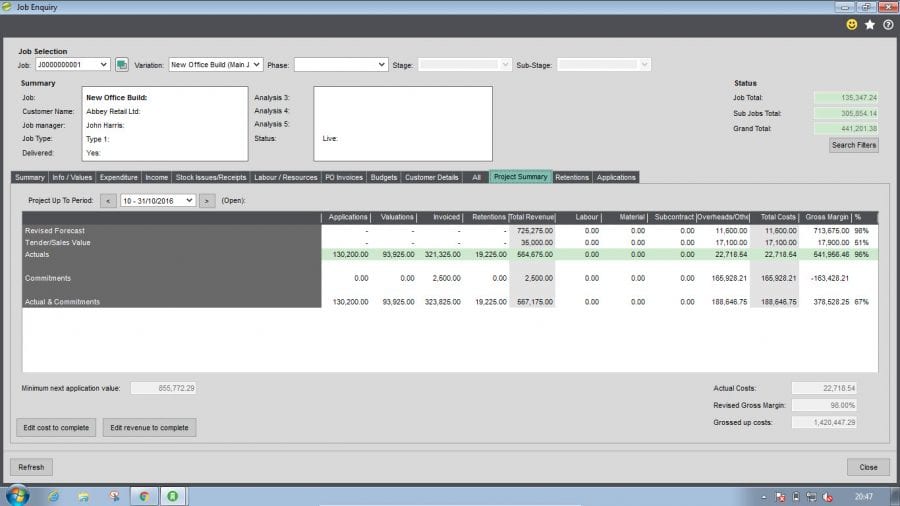

Use Calendars to Identify Scheduling Issues

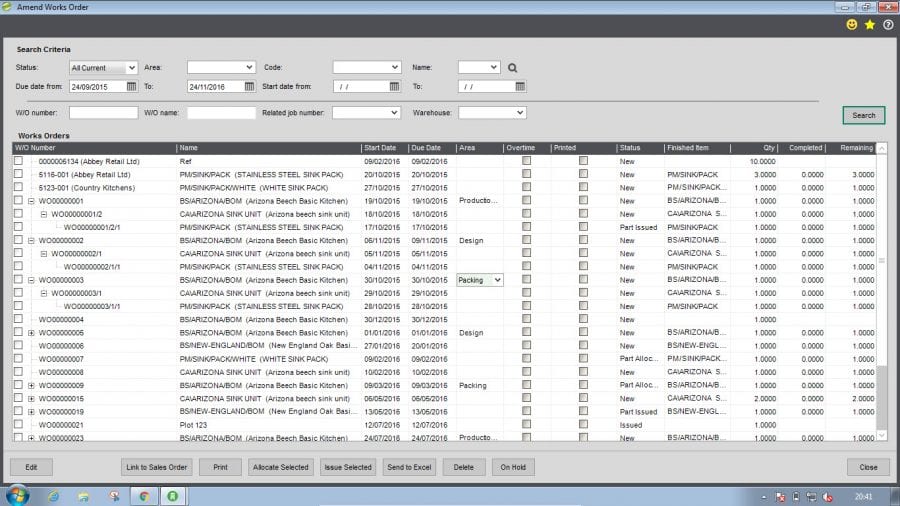

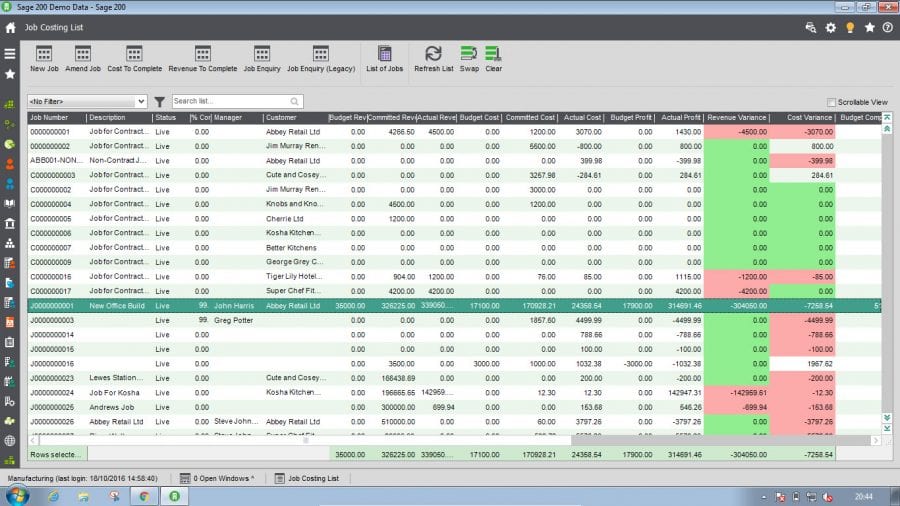

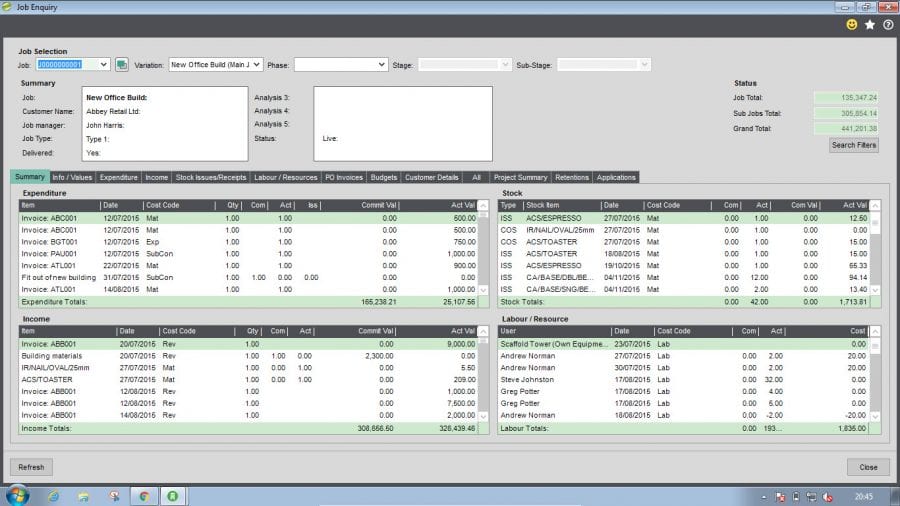

Increase Business Visibility

View & Make Schedule Adjustments

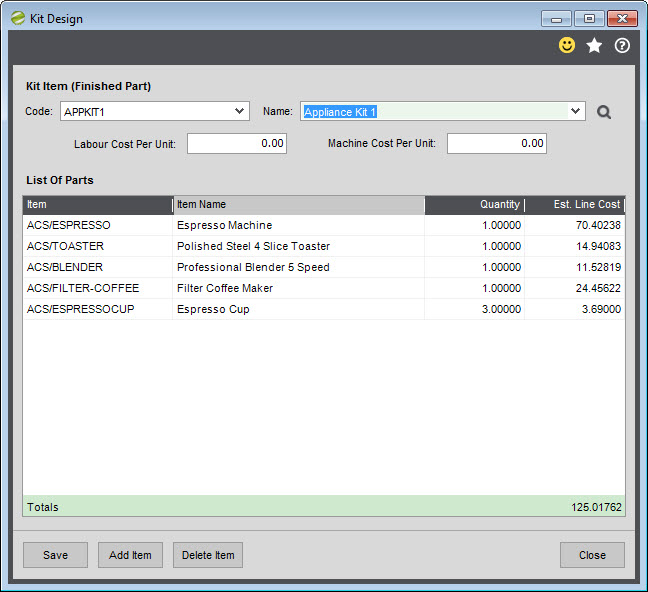

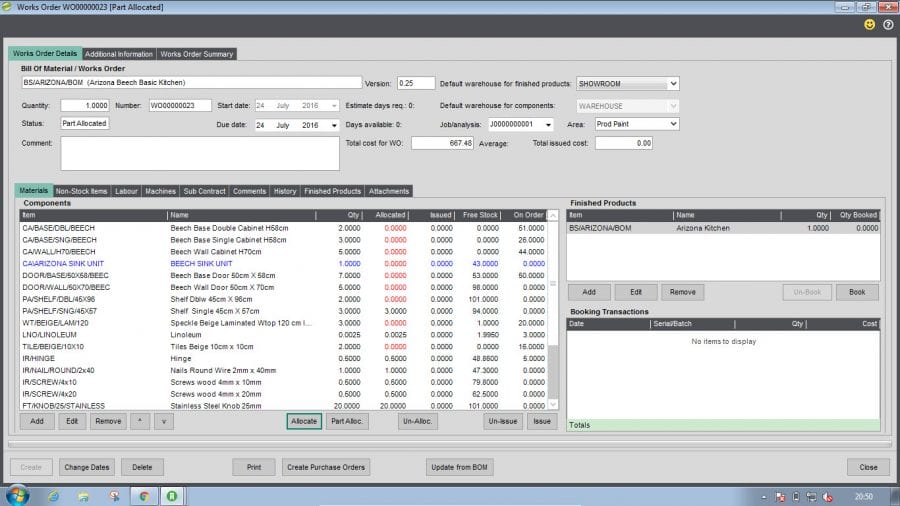

Sage 200 & BOM Integration

Dynamic Material Resource Planning

Flexible and expandable Manufacturing

Quick to implement and easy to use, Sicon Manufacturing integrates with the Sage 200 to provide two-way information, and through the range of features, the modular approach, and the additional integrations to additional solutions, it can grow to meet your needs.

Start with Bill of Materials and Works Orders and expand out to increase the benefits across the business, right through to Shop Floor Data Capture and into Warehousing for parts and finished stock picking/despatch.

Looking for more information?

Features & Benefits of Sicon Manufacturing

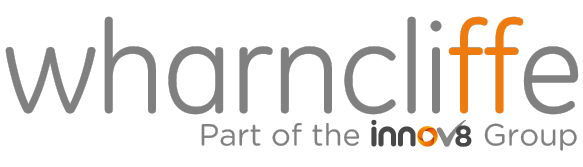

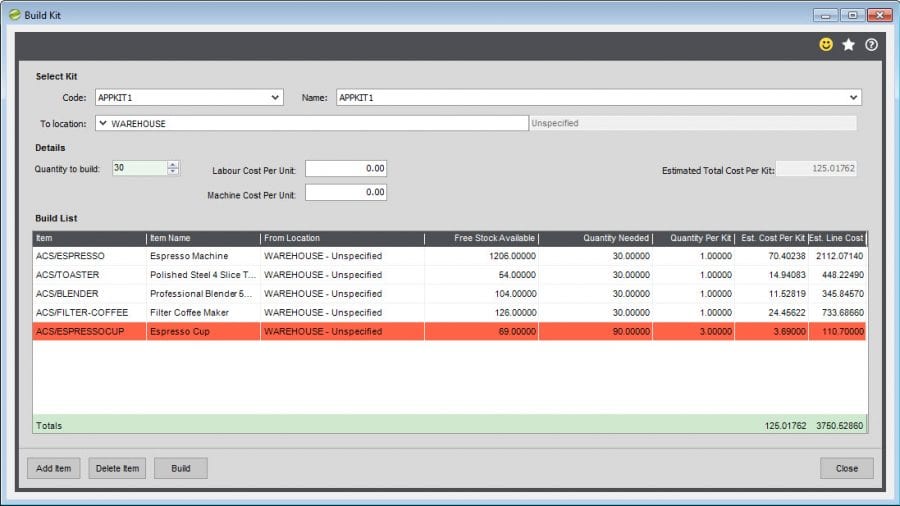

Integrated Sage 200 with Bill of Materials

Create Works Orders using Sage 200’s Bill of Materials, including stock management and sub-assemblies.

View and adjust the Schedule

View operations by resources and teams on a calendar, with drag and drop capabilities for adjustments.

Capacity against the Works Orders

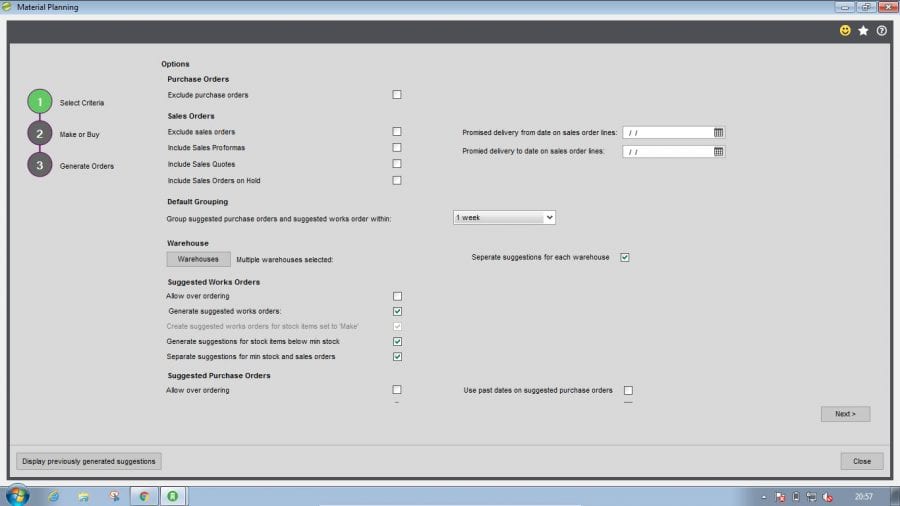

Dynamic Material Resource Planning

Identify stock required from Works Orders, adjust and generate Supplier Purchase Orders.

Save Time

Automate and improve most aspects of manufacturing processing to reduce the administrative and management workload.

Streamline Ordering

Use MRP to identify stock requirements, factoring in supplier ordering parameters, and generate POs.

Capture Shop Floor Data using Barcodes

Use optional barcoding and/or low-cost devices to capture operation progress and elapsed times.

Increase Business Visibility

Ensure your team can see up to date information and progress, allowing better planning & customer updates.

Identify Scheduling Issues using Calendars

Calendar view provides scheduling information, indicating issues and allowing drag-and-drop adjustments.

Looking for something specific?

Looking for more information?

Brochure

Download the Sicon Additions brochure where you will find more information on this solution.

Demonstration

We’d be happy to provide you and your team with a complimentary product demonstration.

Ask a Question

Speak to a member of the Wharncliffe team who will be able to assist with any questions you may have.

Getting in touch…

Getting the answers you need is simple! You can call a member of our experienced team or a speak to our dedicated and knowledgeable sales team who can simply speak to you over the phone, arrange a meeting with you, or arrange a demonstration tailored to your business requirements.